Blog Title goes here that can be anything about Ishtar Bricks or Bricks making process

2023-05-12

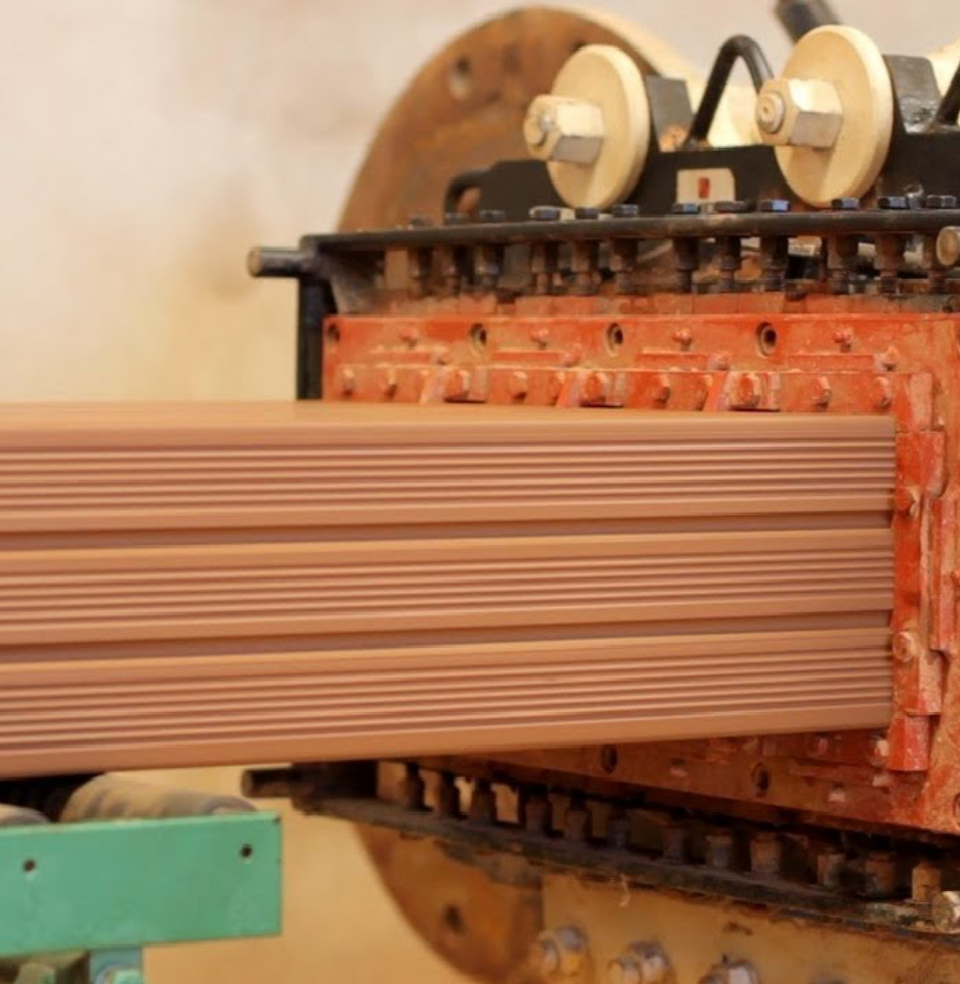

The brick-making process at Ishtar Brick is a harmonious blend of time-honored techniques and modern innovation. It begins with the careful selection of raw materials, including high-quality clay and aggregates, which are meticulously sourced to ensure optimal strength and durability. The raw materials are then finely ground, mixed, and blended to achieve a consistent and homogeneous mixture, ready for the shaping stage. In the shaping stage, the prepared clay mixture is fed into specialized molding machines that precisely form the bricks into their desired shape and size. These machines employ advanced technology to ensure uniformity and precision in every brick produced. Once molded, the bricks undergo a meticulous drying process, where they are carefully placed in controlled environments to gradually remove excess moisture, allowing for proper hardening and minimizing the risk of cracking or deformities. Following the drying process, the bricks enter the firing stage, which is a crucial step in enhancing their strength and durability. Ishtar Brick utilizes state-of-the-art kilns that provide optimal temperature control and uniform heat distribution, ensuring the bricks are fired to perfection. This firing process chemically transforms the clay into a solid, robust structure, enhancing its resistance to weathering, compressive strength, and overall performance. Once fired, the bricks undergo quality inspections to ensure they meet stringent standards before they are ready to be delivered to customers, ready to lay the foundation for exceptional architectural creations.